Electric forklifts are taking over the warehousing industry. Benefits include longer life, fewer emissions, and low repair costs, so it's no surprise that many warehouses are turning to them to improve operational efficiency.

The world will need more than 2.3 billion square feet of new warehouse space by 2035. Because of this expanding need, finding ways to improve safety and efficiency is integral to the industry's continued success.

That's why more and more warehouses are relying on electric elevators to power their operations.

What is an electric forklift?

Electric forklifts do not run on liquid fuel like diesel forklifts, but on electricity. The power source is the battery, which serves two functions - primarily to run the machine, and secondly as a counterweight to stabilize it.

The benefits of electric forklifts include:

1. Long battery life

The long battery life of electric lifts prevents unnecessary stops and operational delays. Lead-acid and lithium-ion batteries last longer under normal use and are more efficient than other power sources.

Heavier loads may cause electric forklifts to lose battery power more quickly, but batteries can also be recharged or replaced quickly. When electric forklifts lose power, workers can quickly and easily replace batteries or recharge electric forklifts during the downtime.

2. Simple maintenance

Electric forklifts have much simpler maintenance needs than gasoline or diesel forklifts. Warehouses can benefit from streamlining forklift maintenance procedures because these machines have fewer parts. Easier maintenance also means workers can more easily perform routine maintenance tasks, such as charging and replacing batteries. This results in greater productivity, as machines have less downtime and people can get back to work sooner.

3. Quiet operation, protect hearing

Warehouses are noisy places, but too much noise can affect the productivity and safety of shop floor workers. Electric forklifts are much quieter than diesel or gasoline powered lifts because they do not have loud intake or exhaust systems. Electric lifts are safer to use and do not affect the operator's health or hearing like other types of forklifts.

4. Low center of gravity is more stable

The stability of a forklift is critical to its efficiency and safety. When lifting heavy objects, the forklift should be kept stable on the ground to protect the driver and other workers around and reduce damage to the goods.

Electric forklifts are generally more stable and reliable than other forklifts due to their low center of gravity and stability provided by heavy-duty battery packs. It also improves morale by letting workers know that safety is paramount to the company.

5. Reduce vibration and operator fatigue, ensuring safety and health

Vibration fatigue occurs on equipment that is subjected to severe vibrations for extended periods of time. Certain frequencies and amplitudes can cause cracks in the machine, which can grow and eventually lead to equipment failure. Electric lifts vibrate less than other types of lifts, so the unit is more stable and less likely to crack or break.

Vibration can also cause operator fatigue and serious injuries. Prolonged sitting on vibrating machines can lead to Operator's Hand Arm Vibration Syndrome (HAVS), which can lead to irreversible vascular and sensory nerve damage and serious health consequences.

Electric forklifts have less vibration than other machinery, so they can ensure the safety and health of operators and reduce the occurrence of HAVS in warehouses.

6. Cheap to repair

Repair costs can add up, especially for warehouses that require many forklifts and machines. Fortunately, electric lifts are relatively inexpensive to repair because there are fewer parts that can break or fail. This cost savings does add up over time.

7. Less emissions, energy saving, environmental protection

The Occupational Safety and Health Association (OSHA) regulates that carbon monoxide levels in warehouses cannot exceed 50 parts per million over an 8-hour average. Warehouses that use diesel or gas-powered forklifts and other machinery must continuously monitor carbon content to ensure they remain compliant.

DIG-DOG produces diesel forklifts and electric forklifts. Our diesel forklifts are mainly sold to areas with colder climates, where batteries consume more power and have a shorter lifespan, while diesel forklifts have more kinetic energy and work more efficiently. And our electric forklifts are sold to other regions, which can give full play to its advantages of environmental protection, energy saving, and convenient maintenance.

If you are still hesitating about how to buy a forklift, please feel free to contact us for professional advice and support.

Exploring the Cheapest Excavators with Top Performance

Exploring the Cheapest Excavators with Top Performance

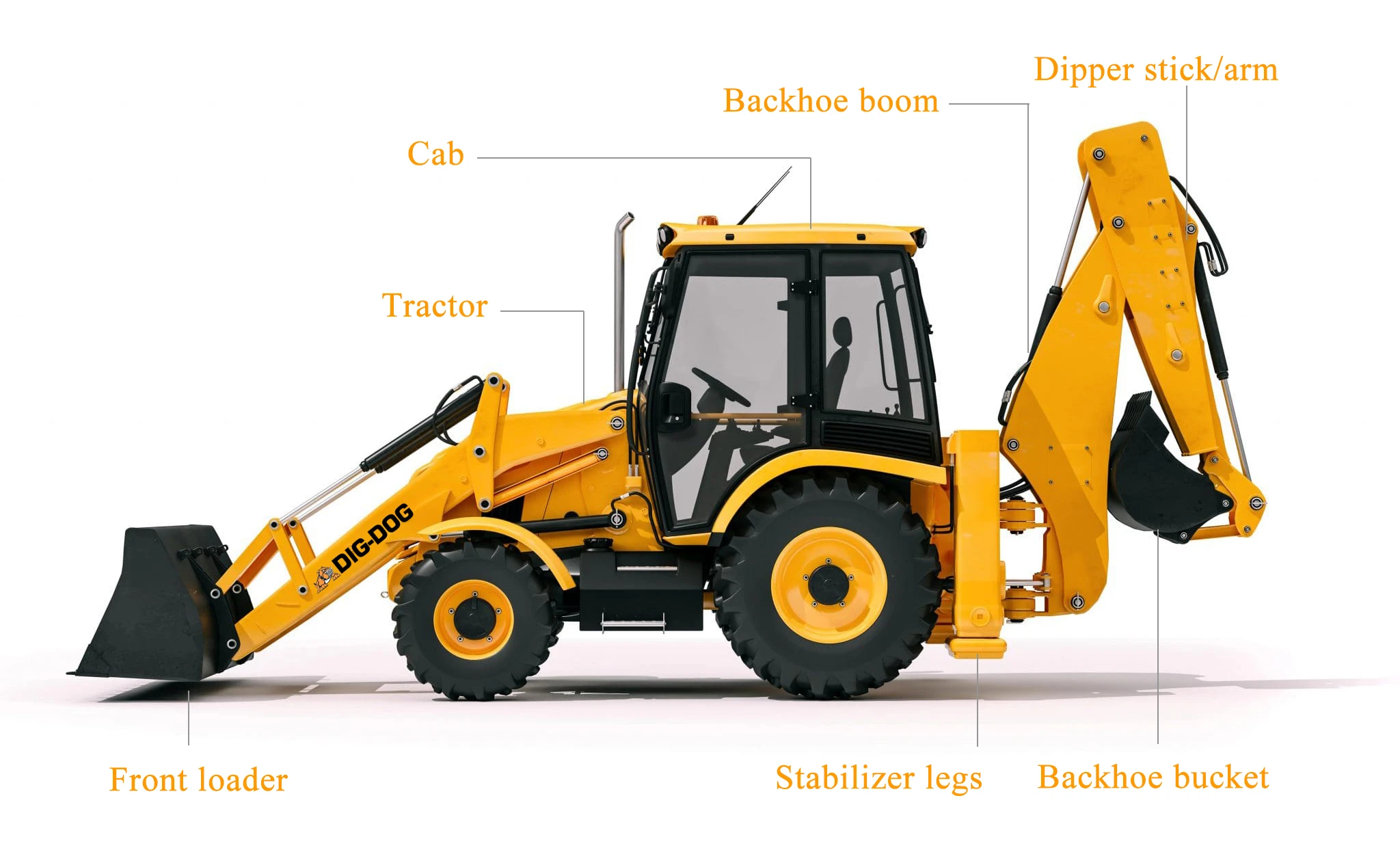

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?