There are numerous reasons why an engineering, manufacturing or mechanical project might require line boring services. Precise work requires precise tools, and often, it'll be necessary to make minute adjustments to workpieces or parts. This article defines and explains the main functions of a line boring machine and its principle applications.

What is a line boring machine?

A line boring machine is a tool that creates clean and accurate holes that have been already cast or drilled. The tooling head itself will consist of a single point cutting tool. Equally, equipment can be designed and manufactured to have a grinding wheel, dependant upon application. However, our line boring machines don't only machine parallel bores; they can cut tapered holes or machine the surface of a workpiece using a facing head.

In the case of a single point tool, the tooling head will be secured in a rotating spindle (Boring Bar). The tooling head will move in a circular motion around the diameter of the existing hole to accurately increase the size. On some machines, the margin of error is less than 0.002%. Usually, a line boring machine will be hydraulic, but they can also be pneumatic or electric.

Applications of line boring

As introduced, there are various reasons why a business may require line boring services. From car manufacturing to shipbuilding, to the power industry and other sectors with complex mechanical needs, there are many workpieces that require fine-tuning. Common applications include:

- Gearbox parts and housings

- Various applications in shipbuilding, including rudder parts and stern tubes

- Driveshaft housing

- A-frame supports

- Hinge pins

- Turbine casing

- Engine Bedplates

- Cylinder Liner locations

- Clevis plate bores

Of course, this is not an exhaustive list. Depending on the specific sector and machinery there are many reasons why engineers may need to use a line boring machine to ensure their workpiece is precise to the nearest micrometres.

What happens during a line boring procedure?

Depending on the nature of a job, the process can change depending on the complexity and specific use of the workpiece. First, an engineer will evaluate the site and review the asset to look at the repair procedure and mounting of the equipment. In some cases, In-Situ Machining Solutions may need to source custom boring bars or repair sleeves.

The engineer will then assess the scope of works. Using precise measuring equipment, the engineer will measure the diameter and roundness of the bore in question. They'll then install and align the equipment to complete the operation. After the boring is complete, the engineer will inspect the bore for accuracy.

Portable line boring services

Whatever your line boring requirements, In-Situ provide portable line boring services across sectors. For information, explore our Services section.

|

|

|

|

| BM-40 |

BWM-50 |

BM-60 |

BWM-50P |

Choosing the Correct Forklift Carriage Class for Your Business Needs

Choosing the Correct Forklift Carriage Class for Your Business Needs

Exploring the Cheapest Excavators with Top Performance

Exploring the Cheapest Excavators with Top Performance

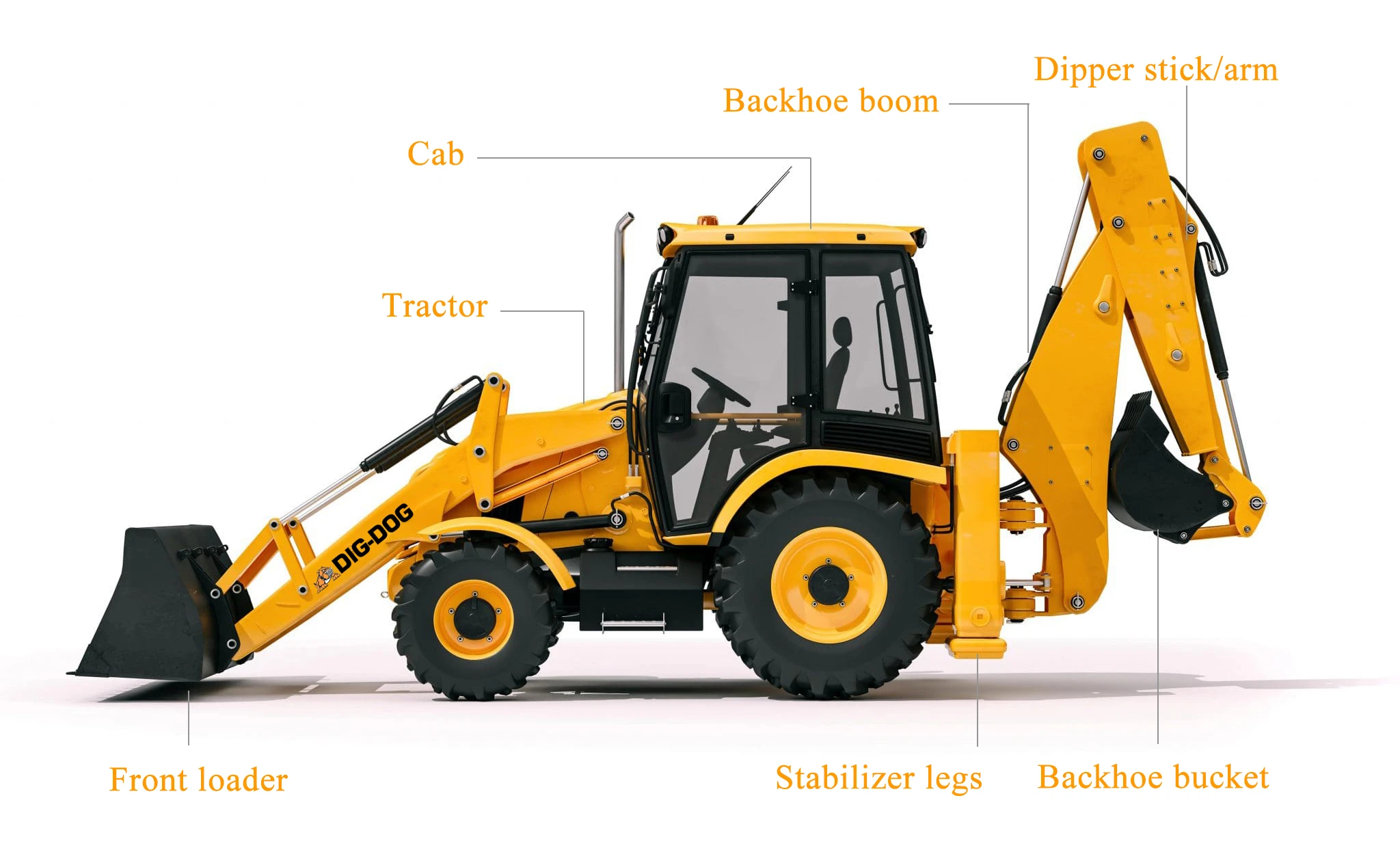

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development