Strong site adaptability: The wheel skid steer loader has strong site adaptability and can operate in small and uneven sites. Its unique wheel skid technology allows the machine to move flexibly in space-constrained environments and easily cope with various terrain challenges.

One machine for multiple purposes: Wheel skid steer loaders are not only suitable for infrastructure construction, industrial applications and other fields, but can also be widely used in dock loading and unloading, engineering site road construction cleaning and other scenarios. By replacing different attachments, it can easily complete various tasks such as bulldozing, shoveling, and transportation, realizing the multi-purpose function of one machine.

Efficient operation: With its powerful power system and stable control performance, the wheel skid steer loader can quickly complete tasks and improve work efficiency during operation. In addition, its compact structure design and excellent maneuverability help reduce operating time and labor costs, and improve overall productivity.

Safe and reliable: The wheel skid steer loader adopts advanced safety technology to ensure safe and reliable operation under various operating conditions. At the same time, it is also equipped with a variety of smart sensors and warning devices to remind surrounding pedestrians or drivers to ensure safety.

The body is compact: the height is only about 1.48 meters, and it can enter various low environments.

Powerful: 45KW engine, which can meet various operating requirements.

Multi-function: A variety of professional working attachments can be replaced to realize various operations such as shoveling, forklift, cleaning, and ice and snow removal.

High efficiency: 360° steering in place. The sand cleaning efficiency per hour is equivalent to 20-30 people working for 4 hours.

Good cost performance and fast return on investment: the daily labor cost saved is about 2,000 yuan.

Challenge a variety of working conditions: It is mainly used in situations where the working site is small and the work content changes frequently. It is also used as auxiliary equipment for large-scale engineering machinery and construction machinery. It is especially suitable for operations in narrow places such as urban infrastructure, roads or construction sites, workshops, warehouses, docks, ship decks and even ship cabins. It is also used for logistics support, site cleaning and project closing of large construction machinery.

Advantages of track skid steer loaders:

Strong off-road capability: The crawler walking mode can operate stably on rugged ground and hillsides with good passability.

Good stability: Because the crawler track has a large contact area with the ground and a low center of gravity, it has good stability during operation.

Strong adhesion: The crawler skid steer loader is not easy to slip on complex terrain such as soft soil, mud or wetlands, and can better exert its adhesion.

Large traction force: The crawler skid steer loader has a large traction force and is suitable for heavy-duty operations such as excavation and bulldozing.

Higher cost: The manufacturing cost of crawler skid steer loaders is relatively high, and the maintenance and upkeep costs are also relatively high.

Disadvantages of track skid steer loaders:

Slow speed: Due to the large moment of inertia and resistance of the crawler walking device, its walking speed is slow.

Easily damaged road surface: When the crawler walking device walks on hard ground, it is easy to cause damage to the road surface.

Advantages of wheel skid steer loaders:

Fast speed: The wheeled walking device has a small moment of inertia and resistance, so its walking speed is fast and it is suitable for fast work on the highway.

Good maneuverability: The wheel skid steer loader can move freely on the road, with easy transition and flexible operation.

Lower cost: Wheel skid steer loaders are cheaper to manufacture and have relatively lower maintenance and upkeep costs.

Not easy to damage the road surface: Since the contact area between the wheeled walking device and the ground is small, it is not easy to damage the road surface.

Disadvantages of wheel skid steer loaders:

Poor stability: Compared with track-type skid-steer loaders, wheel-type skid-steer loaders are less stable, especially when operating on slopes or uneven ground.

Poor passability: Since the contact area of the wheeled walking device is small, its passability is poor and it is not suitable for working on rugged ground or hillsides.

Low adhesion: On complex terrains such as soft soil, mud or wetlands, wheel skid steer loaders are prone to slipping and have low adhesion.

Small traction force: Compared with crawler skid steer loaders, wheel skid steer loaders have smaller traction force and are not suitable for heavy-duty operations.

Wheel skid steer loaders work best on the following terrains:

Flat ground: On flat hard ground, the wheel skid steer loader can operate quickly and stably, giving full play to its maneuverability and flexibility.

Highway pavement: The wheel skid steer loader travels quickly on highway pavement and is easy to transition. It is suitable for highway construction and maintenance operations.

Indoor venues: Due to the small size of the wheel skid steer loader, it can be operated in small and enclosed indoor venues, such as warehouses, workshops, etc.

Soft soil, mud or wet land: Although the wheel skid steer loader is prone to slipping on complex terrain such as soft soil, mud or wet land, it can improve adhesion and improve operating results by changing tires or using anti-skid chains.

Routine inspection: After each use, the machine should be checked for abnormal sounds, leaks, or abnormal operation. Pay special attention to engine oil, coolant and hydraulic oil levels.

Change your engine oil regularly: Follow the manufacturer's recommendations and change your engine oil regularly to ensure proper engine operation.

Cleaning and Lubrication: Clean the machine surface regularly and keep the work area clean. Lubricate critical areas such as bearings and chains.

Tire maintenance: Regularly check tire pressure and wear to ensure the tires are in good condition.

Electrical System Inspection: Regularly check electrical wiring and connections to make sure they are not broken or loose.

Track inspection and adjustment: Make sure the track is appropriately tight. Too loose or too tight may cause damage to the track.

Replacement of wearing parts: Regularly inspect and replace wearing parts, such as buckets, cutting edges, wear strips, etc.

Hydraulic system maintenance: Regularly check the quality and cleanliness of the hydraulic oil, replace and clean if necessary.

Storage environment: The skid steer loader should be stored in a dry, non-corrosive gas place and avoid long-term open storage.

Regular professional maintenance: Carry out regular professional maintenance and upkeep according to the manufacturer's recommendations to ensure that all systems of the machine are comprehensively inspected and maintained.

Tires: Tires are one of the most easily worn components on a skid loader because they come into direct contact with the ground and are often subjected to friction and compression during operation.

Bucket and blade: The bucket is the main operating tool of a slide loader, used for excavation, soil scraping, and other operations. The blade is an important part of the bucket, used for cutting and crushing materials. Due to frequent contact with hard materials, the bucket and blade are prone to wear and tear.

Engine oil and filter: Engine oil plays a lubricating role in the operation of a skid loader, reducing internal friction in the engine. However, engine oil will gradually deteriorate and deposit impurities during use, leading to engine wear. The function of an oil filter is to filter out impurities and particles in the engine oil, preventing them from entering the interior of the engine. Therefore, the oil filter also needs to be replaced regularly.

Hydraulic oil and hydraulic components: The skid-steer adopts a hydraulic transmission system, and the reliability of hydraulic oil and hydraulic components is crucial for the normal operation of the machine. Hydraulic oil plays a role in transmitting pressure, lubrication, and cooling in hydraulic systems, and hydraulic components such as oil pumps, cylinders, and valves also require regular maintenance and replacement.

Electrical components and wires: The control system of the skid loader includes various electrical components and wires, which are also prone to aging or damage and require regular inspection and replacement.

Exploring the Cheapest Excavators with Top Performance

Exploring the Cheapest Excavators with Top Performance

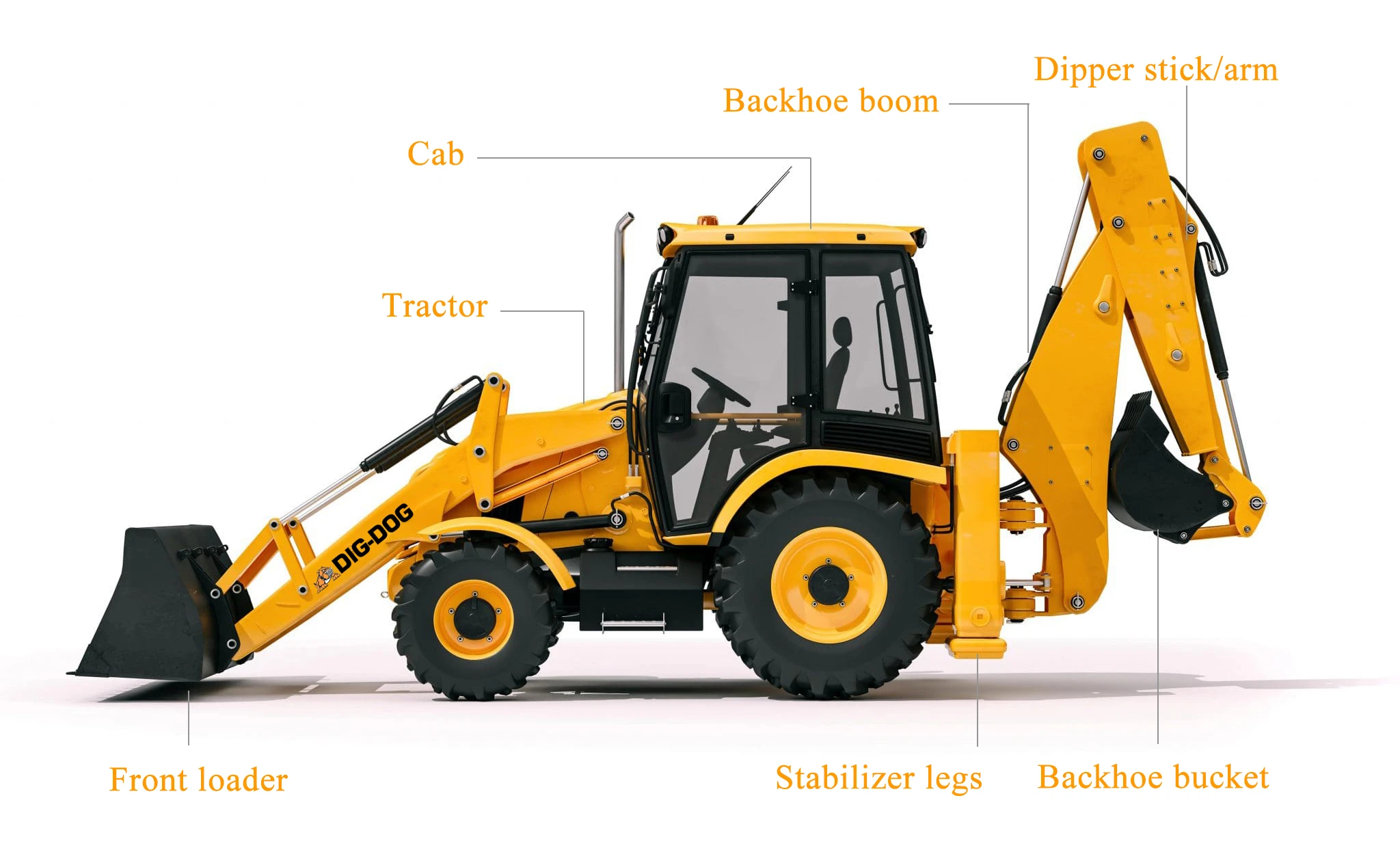

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?